Product Search

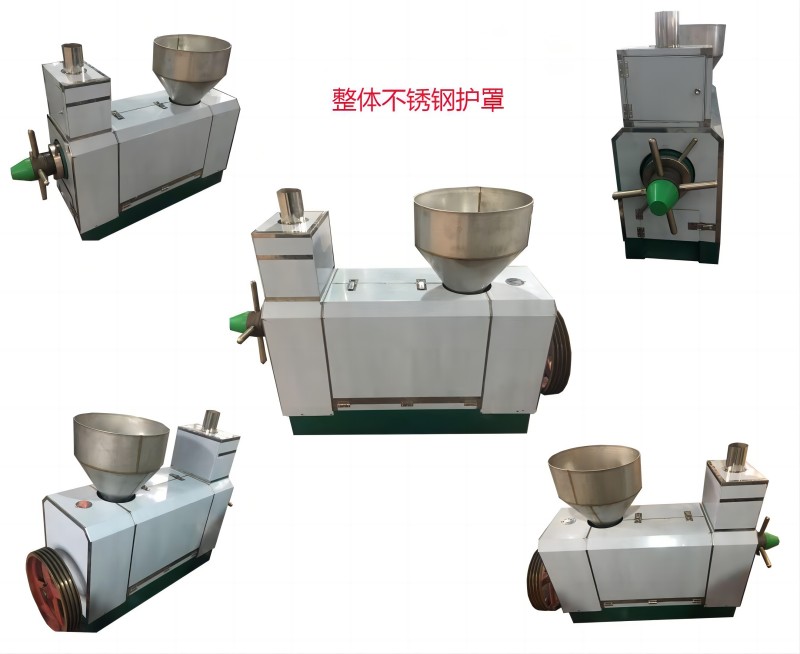

Stainless steel screw oil press

Stainless Steel Oil PressBefore oilseeds are pressed, they should undergo pre-treatment, as the quality of pre-treatment directly affects the oil extraction results. Good pre-treatment can achieve:a. Increased oil yield;b. Higher quality oil and oil cake;c. Improved equipment processing capacity and reduced energy consumption;d. Ensured equipment safety.General oilseed pre-treatment includes:1. Cleaning: Cleaning removes dirt, stones, and metal objects from the oilseeds. Poorly cleaned oilseeds will accelerate parts wear and even damage the oil press, as well as reduce oil yield.2. Shelling and Separation: To fully utilize the oil press’s production capacity and reduce oil loss, shelled oilseeds like peanuts, tung seeds, cottonseeds, and tea seeds should be shelled and separated before pressing. This is an essential step.3. Crushing and flaking: rapeseed and soybeans(cold pressing) can generally be pressed in a whole condition, but crushing and flaking the seeds will improve oil yield. Other oil seeds also perform better when crushed and flaked before pressing.4. Steaming and cooking: the quality of steaming and cooking oilseeds is the key point of increasing oil yield. Steaming and cooking control the moisture content and increase the temperature of oilseeds before pressing. Users can choose suitable steaming and drying equipment to match with the oil press. (Hongyang Company produces the YHCZ series cylindrical cooker, which is available for user selection)

Hydraulic Oil Press

Hydraulic Oil PressXinxiang Hongyang Machinery Co., Ltd. (formerly Xinxiang Hongyang Oil Machinery Factory), located in the National Economic and Technological Development Zone of Xinxiang City, Henan Province, China, is a long-established manufacturer of oil processing equipment. As a member of the China Cereals and Oils Association and the China Feed Industry Association, and a governing unit of the Xinxiang Charity Federation, the company successfully transformed from an old factory in 2004 into a modern oil engineering technology enterprise that integrates product research and development, manufacturing, sales, service, and import and export trade.

Rapeseed Oil Equipment

Rapeseed oil equipment, also known as rapeseed pressing equipment, is developed and produced by Xinxiang Hongyang Company. Its significance lies in extracting high-nutrient edible oil from rapeseed.Pressing MethodThe pressing method, also known as the "physical pressing method," uses external force to squeeze the oil out of the oilseeds without using other chemical solvents, thus avoiding residual organic solvents in the oil. Xinxiang Hongyang Company's pressing process largely retains the effective components in rapeseed—such as polyunsaturated fatty acids, proteins, dietary fiber, vitamins, and trace elements—which are beneficial to human health and suitable for targeted nutritional supplements.Production ProcessHarvesting and screening rapeseed → Rapeseed → Cleaning impurities → Drying → Roasting → Pressing → Pressed rapeseed crude oil → Coarse filtration → Fine filtration → Rapeseed oilRapeseed oil, commonly known as vegetable oil, also called canola oil or fragrant vegetable oil, is a type of edible oil pressed from rapeseed. The oil is golden yellow or brownish-yellow in color and has a certain pungent odor, known as "green odor" among the people, which is due to the presence of glucosinolates. However, premium varieties of rapeseed do not contain this substance.Rapeseed oil is one of the main edible oils in China, primarily produced in the Yangtze River Basin, and in the southwest and northwest regions, with the highest production in the world. The human body can absorb up to 99% of rapeseed oil. It has the effects of softening blood vessels and delaying aging.Since the raw materials for pressing oil are plant seeds, they generally contain a certain amount of seed phospholipids, which are crucial for the development of blood vessels, nerves, and the brain.Rapeseed oil contains very little or almost no cholesterol, making it a safe choice for those who need to control their cholesterol intake.Rapeseed oil has a particularly high content of erucic acid, and there is still debate on whether it can cause myocardial fat deposition and heart damage. Therefore, patients with coronary heart disease and high blood pressure should consume it with caution.According to traditional Chinese medicine, rapeseed oil is sweet, pungent, and warm in nature. It can moisten dryness, kill parasites, reduce fire, and relieve swelling and toxicity.

Single Oil Press Machine

Basic Concept of Oil Press1. Compression Curve of the Pressing Chamberin the pressing chamber of Xinxiang Hongyang Brand screw oil press, due to the increasing width of pressing screw threads, the decreasing screw pitch and the thickening spiral diameter, etc, after raw material enters to feeding section, the material is propelled and compressed as the pressing screw rotates. The degree of compression changes as the material moves through the pressing chamber. Depicting the variation in the compression degree of raw material as it was propelled through the pressing chamber into a drawing, which is called compression curve of pressing chamber. The compression curve of pressing chamber runs as Figure 5-1Figure 5-1 Compression Curve of the Pressing ChamberFrom Figure 5-1, it can be seen that the compression process of the material in the pressing chamber is divided into three sections, analyzed as follows:1. Feeding Section: In the feeding section, the material starts to be compressed, expelling air and moisture, undergoing plastic deformation, and beginning to release oil. Therefore, a small amount of oil droplets and bubbles can be seen at the front end of the pressing cage.2. Pressing Section: The space in the pressing chamber in the pressing section decreases rapidly and regularly. The material is subjected to intense pressure, causing the particles to combine and form a continuous porous mass that expels a large amount of oil. During this process, the material also experiences various types of friction while being compressed.Specifically, pressing screw interrupt, pressing chamber’s knife bar, pressing rod edge’s shearing action cause raw material displacement, breakage and mixing, which continually open oil pathway, allowing for rapid and thorough oil extraction3. Cake Forming Section: In the cake forming section, the material has formed into tile-shaped cakes that advance almost as a single unit, resulting in significant axial compression resistance. At this stage, the compressibility of the tile-shaped cakes is minimal, but it is necessary to maintain high pressure to ensure thorough oil drainage. This process should be extended for an appropriate amount of time, and the axial resistance should be reduced (the geometric dimensions of the screw change very little at this point). If the pressure is reduced too early, the hot cake will expand and loosen, reabsorbing oil, which is detrimental to pressing. The discharged cakes generally expand slightly due to elasticity or expansion.2. Compression Ratio and Total Compression Ratio1. Free Volume of the Screw: The free volume of the screw refers to the space volume enclosed by the screw in each lead (pitch) within the pressing chamber.2. Compression Ratio: The compression ratio is the ratio of the free volumes of the screw in two adjacent leads. If the free volumes of the screw in two adjacent leads are Vn and Vn+1, respectively, then the compression ratio is:3. Total Compression Ratio: The total compression ratio is the ratio of the free volume of the first lead where the material enters to the free volume of the lead at the cake discharge end. If the free volume of the first lead is V_in and the free volume of the lead at the cake discharge end is V_out, the total compression ratio ε is:

Pressure leaf filter machine

The pressure leaf filter machine is a type of filtering equipment developed by our Xinxiang Hongyang factory based on the early study of the Dutch AMA filter machine. This machine has been successfully used in various vegetable oil plants, with all technical performance indicators reaching the level of similar foreign products. This product fills a domestic gap and represents a new generation of filtration equipment that can replace imports and upgrade existing technology.Uses and Characteristics:The pressure leaf filter machine is ideal for solid-liquid separation in the production processes of oils, chemicals, light industry, food, pharmaceuticals, and other industries.its features run as the following:(1) Compact structure, small area occupation;(2) Excellent filtration efficiency with low losses;(3) Mechanical slag discharge, low labor intensity;(4) High productivity;(5) Two machines can be operated in parallel for continuous production.

bag filter machine

The bag filter machine is a sophisticated, energy-efficient, high-efficiency, and versatile filtration equipment. This series of filters operates under pressure, with the liquid to be filtered when entering through the inlet and passing through a filter bag where impurities and particles are trapped. Different types of filter bags with varying materials and filtration precision can be selected based on the type of liquid and particles. Changing filter bags is convenient and involves minimal material consumption.Applications of bag filter machines include edible oils, paints, beer, pharmaceuticals, chemicals, milk, mineral water, hot solvent emulsions, industrial water, sugar solutions, resins, inks, industrial wastewater, fruit juices, waxes, and others.

Extraction mixed oil filter machine

The XHL mixed oil filter machine is a mechanical device used for filtering mixed oil obtained after the extraction of vegetable oils. The filtered mixed oil significantly reduces the content of solid residues, thereby improving the evaporation efficiency of the mixed oil. It plays a crucial role in enhancing the quality of crude oil and facilitating the comprehensive utilization of by-products.Compared to other mixed oil filtration devices, this equipment offers several advantages:- Compact structure with excellent filtering performance, reducing impurities in the mixed oil to around 0.2%.- Continuous operation capability without easily getting clogged, easy dismantling, and low labor intensity.- Effectively prevents fouling and liquid flooding in evaporators and stripper due to high impurity content in mixed oil- Improves the quality of extracted crude oil and provides optimal conditions for the extraction of phospholipids from plants.Equipment Overview:The XHL mixed oil filter machine consists of a horizontal cylindrical body supported by a support base with left and right end caps. Inside the cylindrical body are several circular filter plates fixed on a hollow shaft, which rotates along with the shaft. A set of several container nozzles are mounted on the horizontal cylinder for periodic cleaning of the filter plates. At the bottom of the cylinder, there is a residue collection hopper, and a ZW-type self-priming sewage pump is used to discharge the residue back to the extractor. The inlet for mixed oil and outlet for free gas are located at the upper part of the cylinder. The hollow shaft is driven by a chain transmission device for rotation. The filtered clean mixed oil is collected through the hollow shaft and pumped out via a rotary joint.

Old-fashioned plate and frame filter press

The plate and frame filter press is a pressurized batch operation filtration device. the suspension liquid is pumped into each filter chamber of the filter press by a feeding pump, where under pressure, solid-liquid separation of various suspension liquid takes place between filter cloths and oil slags.notes It is widely used in industries such as chemical, petroleum, pharmaceutical, fuel, metallurgy, food, citric acid, sugar production, and synthetic fibers.Notes:1. The 1000 and 1250 series refer to the external dimensions of the plates; the 630 and 800 series also include box filter presses..2. Filter plates of various series of filter presses are made of materials such as cast iron, polypropylene, rubber, stainless steel, aluminum-bronze, etc.3. We can customize the filter machines if customers have any special requirement.4. "Machine weight" varies with the type of material; cast iron types are heavier than polypropylene and rubber types.5. For further detailed technical parameters, please refer to the user manual.

Horizontal pressure leaf filter

Overviewthe WYL horizontal closed automatic filter is a high-efficiency, energy-saving, and precision purification device with automatic closed filtration developed by Xinxiang Hongyang Machinery Co. Ltd. It is widely used in ....(1) Completely sealed filtration, no leakage, no environmental pollution.(2) Automatic pulling-out structure of filter mesh plate for easy observation and residue cleaning.(3) Double-sided filtration with large filtration area and high capacity for residues.(4) Vibration discharging to reduce labor intensity.(5) Hydraulic control for automated operation.(6) The equipment can be designed as a large-capacity, large-area filtration system.Applications(1) Recovery of dry filter cakes, semi-dry filter cakes, and clarified filtrates.(2) Chemical industry: sulfur, aluminum sulfate, composite aluminum compounds, plastics, dye intermediates, bleaching liquids, lubricant additives, polyethylene.(3) Food industry: sugar juice, oils and fats, dewaxing, decolorization, defatting.

Automatic Sludge discharge filter machine

This equipment is a widely-used new type vertical automatic sludge discharge leaf filter. Its unique design of filter screen plates eliminates the need for filter papers or cloth, significantly reduces filtration cost.it operates with fully sealed filtration, ensuring no pollution or loss of oil materials. The vibration discharge feature greatly reduces labor intensity. The machine has the characteristics of realizing continuous operation, automatic valve discharge and low oil percentage in residue and so on.Also known as: vibration discharge filter, automatic sludge discharge filter, leaf filter, vibrating leaf filter., vibrating leaf filter, vibrating leaf filter..this machine is researched and developed by Xinxiang Hongyang Company based on the industrial international technology in order to solve the common problems of solid-liquid separation in different industries. This filter leaf adopts special stainless steel filter screens known for their long life, high output, and high precision. It is suitable for filtering and separating processes in industries such as oils, chemicals, and pharmaceuticals, particularly effective in filtering and addressing issues like the difficulty of filtering cottonseed and rapeseed oils in the oil industry.Features of the automatic sludge discharge filter (oil filter):1. No need for filter cloths or papers, significantly reducing filtration costs.2. Fully enclosed operation, environmentally friendly with no material loss.3. Vibration discharge reduces labor intensity and allows for continuous operation.4. Pneumatic valve sludge discharge significantly reduces labor intensity for workers.5. Can fully replace plate and frame filters for filtering residue or activated carbon (diatomite) in liquids, making it the preferred equipment in the filtration industry.Applications of the automatic sludge discharge filter (oil filter):1. Petrochemicals: polyethers, diesel, lubricants, white oils, transformer oils.2. Mineral oils and base oils: dibutyl phthalate, dioctyl ester.3. Oils and fats: crude oil, bleaching earth, gasification oil, winterized oil, etc.4. Food: gelatin, salad oil, starch, sugar juice, monosodium glutamate, milk, etc.5. Pharmaceuticals: hydrogen peroxide, vitamin C, glycerin, etc.6. Coatings: varnish, resin paint, genuine lacquer, 685 varnish, etc.

Vertical Oil Rendering Pot

Vertical Oil Rendering PotRendering method: Typically used in the processing of animal fats, where animal fats are heated at high temperatures to destroy all fat and oxidative enzymes in the tissue. Even with residual solids present after rendering, the fats do not spoil. therefore the rendering method developed by Xinxiang Hongyang Machinery CompanyExtraction process is considered a more advanced processing method in terms of hygiene. However, the temperature during rendering should not be too high, and the duration should not be too long to prevent partial fat decomposition and increase in free fatty acids in the oil. Excessively high temperatures can also cause animal tissues to char, affecting the sensory characteristics of the products.This vertical oil rendering pot is suitable for refining various edible-grade animal fats such as edible lard, edible chicken fat, edible duck fat, and edible beef fat.Extraction ProcessWith the scale of pig farming becoming increasingly large-scale in the market, many large-scale pork processing enterprises have substantial amounts of pig fat that need to be processed and utilized. currently, Xinxiang Hongyang Machinery Co. Ltd has developed a complete set of pig oil rendering equipment production line, utilizing new technology and equipment to extract refined pig oil. The products are sold worldwide, with numerous exemplary projects installed across various provinces. including Yunnan, Guizhou, Inner Mongolia, Chongqing, Sichuan, and Henan.The standardized large-scale production line process generally includes: mincing, conveying, material separating, melting and boiling, oil slag separation, filtration, rendering crude oil and refining.Refining process includes dephosphorization, degumming, dehydration, deodorization, deacidification, decolorization, etc. Animal oil must be refined before it can be consumed. This type of oil generally has a light color and becomes snow white after refining with equipment of Xinxiang Hongyang Machinery Co. Ltd

Animal and poultry harmless disposal equipment

This equipment utilizes Hongyang's drying and chemical processing technology. Its main features include high temperatures that effectively sterilize animal and poultry carcasses, followed by processes such as drying, degreasing, and pulverizing to completely break them down into oil and meat bone powder. The oil can be used for industrial purposes, animal feed, and biodiesel, while the meat bone powder can be used for high-protein feed and organic fertilizer. Both products have high market potential and are widely applied in agriculture, fisheries, livestock farming, machinery, and chemical industries. The entire equipment system is automated during processing, ensures a fully sealed and pollution-free process, and achieves environmentally friendly, harmless, recyclable, and highly efficient results, garnering significant so it wins significant attention and praise from customers.This product is designed for the harmless treatment of meat carcasses and products of animals such as pigs, cattle, sheep, horses, donkeys, mules, camels, rabbits, chickens, and ducks that may be infected with contagious diseases, parasitic diseases, or toxic diseases.It is suitable for the harmless treatment of diseased tissues, organs, and deteriorated harmful products from animal slaughterhouses.It is used for the harmless treatment of slaughterhouse by-products and glands.It is also applicable for the harmless treatment of dead animals with unknown causes of death or infected animals in animal feed factories and isolation facilities.The product utilizes a vacuum negative pressure system for safety, with a large heating area and fast heating speed, significantly reducing the time required for harmless treatment.The equipment series processes diseased pigs and other diseased animal products by boiling them at high temperatures to thoroughly eliminate pathogens, while simultaneously extracting oil, meat powder, and bone meal as by-products, ensuring a simple structure and easy operation.