Product Search

Rapeseed Oil Equipment

Rapeseed oil equipment, also known as rapeseed pressing equipment, is developed and produced by Xinxiang Hongyang Company. Its significance lies in extracting high-nutrient edible oil from rapeseed.Pressing MethodThe pressing method, also known as the "physical pressing method," uses external force to squeeze the oil out of the oilseeds without using other chemical solvents, thus avoiding residual organic solvents in the oil. Xinxiang Hongyang Company's pressing process largely retains the effective components in rapeseed—such as polyunsaturated fatty acids, proteins, dietary fiber, vitamins, and trace elements—which are beneficial to human health and suitable for targeted nutritional supplements.Production ProcessHarvesting and screening rapeseed → Rapeseed → Cleaning impurities → Drying → Roasting → Pressing → Pressed rapeseed crude oil → Coarse filtration → Fine filtration → Rapeseed oilRapeseed oil, commonly known as vegetable oil, also called canola oil or fragrant vegetable oil, is a type of edible oil pressed from rapeseed. The oil is golden yellow or brownish-yellow in color and has a certain pungent odor, known as "green odor" among the people, which is due to the presence of glucosinolates. However, premium varieties of rapeseed do not contain this substance.Rapeseed oil is one of the main edible oils in China, primarily produced in the Yangtze River Basin, and in the southwest and northwest regions, with the highest production in the world. The human body can absorb up to 99% of rapeseed oil. It has the effects of softening blood vessels and delaying aging.Since the raw materials for pressing oil are plant seeds, they generally contain a certain amount of seed phospholipids, which are crucial for the development of blood vessels, nerves, and the brain.Rapeseed oil contains very little or almost no cholesterol, making it a safe choice for those who need to control their cholesterol intake.Rapeseed oil has a particularly high content of erucic acid, and there is still debate on whether it can cause myocardial fat deposition and heart damage. Therefore, patients with coronary heart disease and high blood pressure should consume it with caution.According to traditional Chinese medicine, rapeseed oil is sweet, pungent, and warm in nature. It can moisten dryness, kill parasites, reduce fire, and relieve swelling and toxicity.

Large Rapeseed Oil Extraction Equipment

The large rapeseed oil extraction equipment, also known as rapeseed oil extraction equipment, is developed and produced by Xinxiang Hongyang Company. Its significance lies in extracting the high-nutrient edible oil from rapeseed.Principle and ProcessThe production process of rapeseed oil generally involves two methods: pressing and extraction (refining).Pressing MethodThe pressing method, also known as "physical pressing," involves using external force to squeeze the oil out of the oilseeds without the use of other chemical solvents, thus avoiding the residue of organic solvents in the oil. Xinxiang Hongyang Company's pressing process retains a significant portion of the effective components of rapeseed, including polyunsaturated fatty acids, as well as proteins, dietary fiber, vitamins, trace elements, and other nutrients beneficial to the human body, making it more suitable for specific health supplements.Extraction Method (Refining Method)The extraction method, also known as the refining method, involves using organic solvents (such as gasoline, ethanol, etc.) to extract the oil from the oilseeds. The extraction method uses solvent oil (light gasoline No. 6) to extract the oil from the raw material after soaking, followed by high-temperature extraction to remove the oil. Initially, the "oil" extracted is a mixture of organic solvents and oil, which is not edible and must undergo a series of refining processes (such as degreasing, degumming, dehydrating, deodorizing, deacidifying, decolorizing, etc.) before it can be consumed. This oil generally has a lighter color and a weaker or no natural seed flavor. The extraction process can almost extract all the oil from the oilseeds, making it a highly economic and widely used method in the modern oil industry.Production ProcessThe production process includes harvesting and selecting rapeseeds, cleaning impurities, drying, roasting, pressing, crude rapeseed oil pressing, coarse filtering, fine filtering, and finally, rapeseed oil.Rapeseed OilRapeseed oil, commonly known as rapeseed oil or vegetable oil, is an edible oil extracted from rapeseeds. It has a golden or brownish yellow color and a slight irritating odor, often referred to as "green odor." This odor is due to the presence of a certain amount of sinapine, but the best rapeseed varieties do not contain this substance.It is one of the main edible oils in China, mainly produced in the Yangtze River basin and the southwest and northwest regions, with the world's highest production. The human absorption rate of rapeseed oil is very high, reaching 99%. Rapeseed oil has the effect of softening blood vessels and delaying aging.Since the raw material for oil extraction is the seed of a plant, it usually contains a certain amount of seed lecithin, which is very important for the development of blood vessels, nerves, and the brain.Rapeseed oil contains little or no cholesterol, so people who need to control their cholesterol intake can consume it with confidence.Rapeseed oil has a particularly high content of erucic acid, which may or may not cause myocardial fat deposition and damage the heart. Therefore, patients with coronary heart disease and hypertension should be cautious and consume it in moderation.According to traditional Chinese medicine, rapeseed oil is sweet, pungent, and warm in nature, and can moisten dryness, kill insects, dissipate fireballs, and eliminate swelling and toxicity.

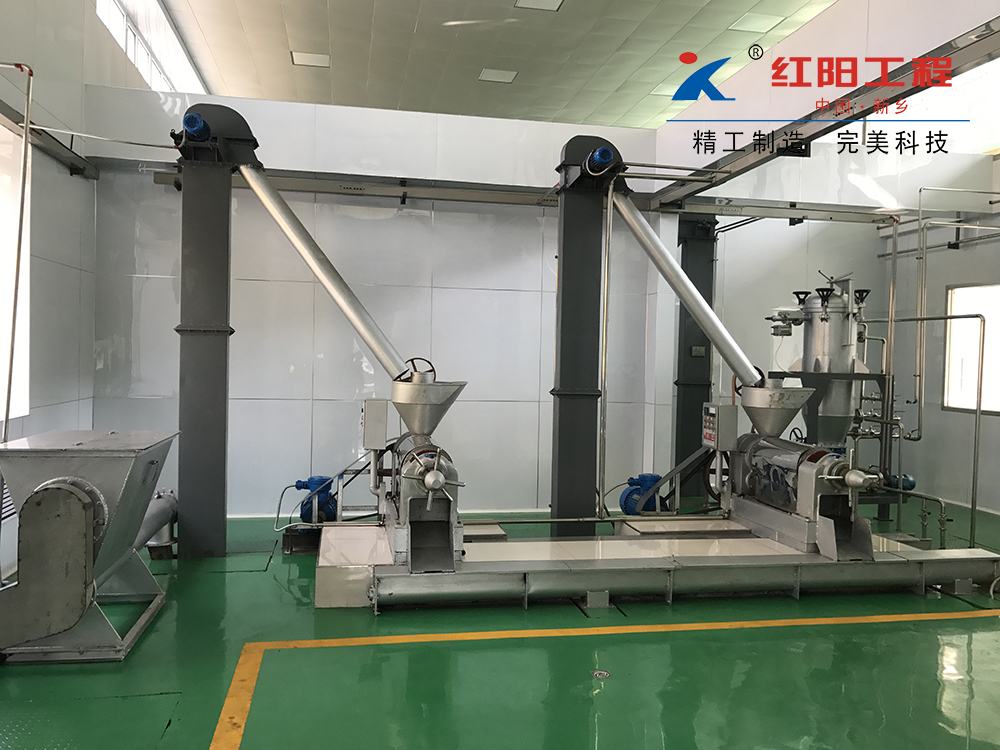

Medium Scale Complete Oil Extraction Project

Mid-Sized Complete Oil Extraction PlantThis process employs a large-scale screw oil press for oil extraction. The screw oil press is a widely used device for pressing oil extraction, characterized by its ability to handle a large continuous workload, short dynamic pressing time, high oil extraction rate, and low labor intensity.The main part of the screw oil press is the press chamber, which is composed of the press cage and the screw shaft rotating within the cage. the working process utilizes the continuous rotation of the screw shaft to drive the screw and create pressure in the press chamber as the pitch decreases or the root diameter increases. The oil is squeezed out through the gaps of the press cage, while the residue is compressed into crumbly cake pieces that are continuously discharged from the end of the screw shaft. Oil extraction can be generally divided into three stages: feed (pre-pressing) stage, main pressing (oil extraction) stage, and cake forming stage.SummaryThe 200-type oil press is suitable for extracting vegetable oils and can process various materials such as rapeseed, peanut kernels, sesame, cottonseed kernels, soybeans, coconuts, rapeseed, sunflower seeds, hempseed, etc. (According to user needs, the press screw can be replaced to extract oil from oil-containing materials such as rice bran.)Features1. The main shaft, press screw, press bars, gears, and other major parts of this machine are all made of alloy steel and undergo hardening treatment. Despite operating under high temperatures and friction wear, they are durable and long-lasting.2. The combination of steaming and roasting is another feature of this equipment. It can be adjusted according to the different temperature requirements of various oil materials before pressing, thus obtaining high-quality oil.3. From material feeding, steaming, roasting, to oil extraction and cake discharge, the process is fully automatic and continuous, making it easy to manage and saving labor.

Small Scale Fragrant Oil Pressing Equipment

The pressing methods for the main oil crops are as follows:1. Rapeseed: Due to the varying moisture content of raw materials from north to south, add water before roasting, 4-6% for the north, and no water for the south (depending on the moisture content of the raw material itself). Roast with high heat until the rapeseed becomes hot to the touch and starts to crackle, then switch to low heat to roast until the rapeseed opens and turns brownish red. During the roasting process, no water should be added. The rapeseed temperature entering the press should be 120-130 degrees Celsius, with a moisture content of about 1-1.5%. The suitability of the roasting can be observed from the flow of oil and the state of the cake. If the roasting is appropriate, the cake flows smoothly with minimal residue, and the cake is 1-1.5mm thick and brownish red.2. Peanut Kernel: Before roasting, soak the peanut kernel in water once. During the roasting process, add an appropriate amount of water to maintain the kernel's softness and moisture. Roast the kernel until it is eighty percent cooked, so that it can be separated from the skin and breaks into two halves. The cake thickness should be 0.7mm, and it should be long and wrinkled, with smooth oil extraction.3. Cottonseed Kernel: Roast the oilseed to a light yellow color before pressing, at a temperature of 120-130 degrees Celsius, and adjust the moisture content according to the north-south variations. The cake thickness should be 1-1.5mm.4. Soybean: Roast the soybean until it is sproutable before pressing, at a temperature of 120-130 degrees Celsius, and the cake thickness should be 0.7mm. However, the cake from a single pressing can be too charred, resulting in significant protein loss. Therefore, it is generally better to adopt a two-step pressing process. Roast the soybean to about sixty or seventy percent done, enter the press at 80-100 degrees Celsius, with a moisture content of 5-6%. The first pressing cake thickness should be 1.5-2mm, and the second pressing cake thickness should be 0.7mm, with a long and wrinkled shape, high oil extraction rate, and increased processing capacity.Screw Oil Press: The screw oil press is a commonly used device for pressing oil extraction. It has advantages such as continuous processing, short dynamic pressing time, high oil extraction rate, and low labor intensity.The main part of the screw oil press is the press chamber, which consists of the press cage and the screw shaft rotating inside the cage. the working process utilizes the continuous rotation of the screw shaft to drive the screw and create pressure in the press chamber as the pitch decreases or the root diameter increases. The oil is squeezed out through the gaps of the press cage, while the residue is compressed into crumbly cake pieces that are continuously discharged from the end of the screw shaft. Oil extraction can be generally divided into three stages: feed (pre-pressing) stage, main pressing (oil extraction) stage, and cake forming stage.

Cold pressing walnut oil extraction equipment

The walnut oil production equipment process adopts a pure physical pressing method to extract oil, with a unique process developed by Xinxiang Hongyang that solves the problem of aroma generation and retention in walnut oil production. The raw material is required to undergo de-dusting and de-stoning before being broken and pressed to separate the oil from the oilseeds. after pressing, the product is obtained by using Xinxiang Hongyang Machinery Co. Ltd’s natural filtration and purification technology.This process eliminates the use of solvents, alkalis, and ultra-high temperature refining used in extraction oil, thereby preserving the natural nutritional components of the finished oil and maintaining its original flavor, rich aroma, without solvent residues or soap content. It is a walnut oil production process that combines modern and traditional techniques.Pure Physical Walnut Oil ProcessThe cleaned raw material is then graded, with the top-quality walnuts sold as food directly, while the broken and crushed walnuts enter the oil press.The crude oil from the press is then clarified in the oil tank, filtered through the leaf filter, and de-gummed using our company's unique centrifugal de-gumming method. After drying, cooling, and plate frame filtration, it enters the finished oil storage tank. The use of centrifugal de-gumming shortens the natural sedimentation time of the gum and reduces the investment in equipment and building construction.Process Features:· All process equipment is continuous and mechanized;· Computerized automation control system with computer display, control, and recording; the workshop has an independent control room for centralized control; equipped with a large-screen simulative control panel and automatic alarm, interlock control; automatic control instruments for temperature, pressure, material level, and flow ensure that the workshop operation can be understood and controlled from the control room;· Equipped with a powerful dust removal system to meet production and environmental protection requirements;· The light and fine impurities removed can be returned to the meal or stored and transported separately.Process Flow DiagramRaw Material → Receiving → Steel Silo → Measurement → Cleaning and De-dusting → Crushing → Conditioning → Pressing → Crude Oil → De-gumming and Refining → Rich Aroma Walnut Oil → Oil Tank

Hempseed Oil Extraction Equipment

The hempseed oil extraction equipment, also known as flaxseed oil extraction equipment, is developed and produced by Xinxiang Hongyang Company. Its significance lies in extracting the high-nutrient edible oil from hempseed.The production process of hempseed oil generally involves the pressing method and the extraction method (refining method) developed by Xinxiang Hongyang Company.Pressing MethodThe pressing method, also known as "physical pressing," involves using external force to squeeze the oil out of the oilseeds without the use of other chemical solvents, thus avoiding the residue of organic solvents in the oil.Xinxiang Hongyang Company's production process retains the effective components of hempseed, including polyunsaturated fatty acids, as well as proteins, dietary fiber, vitamins, trace elements, and other nutrients beneficial to the human body, making it more suitable for specific health supplements.Extraction Method (Refining Method)The extraction method, also known as the refining method, involves using organic solvents (such as gasoline, ethanol, etc.) to extract the oil from the oilseeds. The extraction method uses solvent oil (light gasoline No. 6) to extract the oil from the raw material after soaking, followed by high-temperature extraction to remove the oil. Initially, the "oil" extracted is a mixture of organic solvents and oil, which is not edible and must undergo a series of refining processes (such as degreasing, degumming, dehydrating, deodorizing, deacidifying, decolorizing, etc.) before it can be consumed. This oil generally has a lighter color and a weaker or no natural seed flavor. The extraction process can almost extract all the oil from the oilseeds, making it a highly economic and widely used method in the modern oil industry.Production ProcessThe production process includes harvesting and selecting hempseeds, cleaning impurities, shelling, crushing, pressing, crude hempseed oil pressing, coarse filtering, fine filtering, low-temperature crystallization and maturation, low-temperature filtering, and finally, hempseed oil.Hempseed contains 6% to 10% of hemp gum. Hemp gum is a pectin-like substance mainly composed of polysaccharides, containing 12% protein, about 17% pectin, starch, minerals, etc., which can be used as food additives, cosmetic raw materials, and pharmaceutical raw materials.Nutritional content of 100 grams of hempseed oil: Calories (900.00 kcal), Fat (100.00 g), Vitamin E (389.90 mg), Calcium (3.00 mg), Phosphorus (5.00 mg), Sodium (0.60 mg), Magnesium (1.00 mg), Iron (0.20 mg), Zinc (0.30 mg), Copper (0.02 mg), Manganese (0.03 mg).Hempseed OilHempseed oil is extracted from hempseed. Hempseed (flaxseed or linseed) is the seed of the flax plant, an annual or perennial herbaceous plant of the flax family. Hemp is one of the oldest fiber crops in the world, with many varieties, but can be roughly divided into three types: oil hemp, fiber hemp, and oil-fiber dual-purpose hemp. The seeds of all these types can be pressed for oil, making hemp one of the world's top ten oil crops, ranking seventh in terms of production. Oil hemp is mainly produced in Canada, China, Argentina, and the United States. China introduced hemp seeds in the 2nd century BC by Han Dynasty envoy Zhang Qian during his mission to the Western Regions. It was first planted in Ningxia, Heilongjiang, Inner Mongolia, Shanxi, and Northeast China, initially mainly for medicinal use, until the 16th century when it was used to extract oil from its seeds. Nowadays, hempseed is one of China's main economic crops and a major oil crop in the northwestern, northwestern, and northeastern regions with high cold areas.

Sunflower Seed Oil Extraction Equipment

Sunflower Seed Oil Extraction EquipmentThe sunflower seed oil extraction equipment currently developed and produced by Xinxiang Hongyang Machinery Co. Ltd is significant for its ability to extract the highly nutritious edible oil from sunflower seeds.IngredientsSunflower seeds, the fruit of the sunflower, are used for both consumption and oil production. Rich in unsaturated fatty acids, various vitamins, and trace elements, sunflower seeds are a popular snack and a source of edible oil due to their pleasant taste.every 100 grams of sunflower seeds contain 597 calories, 23.9 grams of protein, 49.9 grams of fat, 13 grams of carbohydrates, 72 milligrams of calcium, 5.7 milligrams of iron, 238 milligrams of phosphorus, 562 milligrams of potassium, 5.5 milligrams of sodium, 2.51 milligrams of copper, 264 milligrams of magnesium, 6.03 milligrams of zinc, 1.21 micrograms of selenium, 5 micrograms of vitamin A, 0.36 milligrams of vitamin B1, 0.2 milligrams of vitamin B2, 34.53 milligrams of vitamin E, 0.03 milligrams of carotene, 280 micrograms of folic acid, and 4.8 milligrams of niacin.Principle and ProcessThe production of sunflower oil generally involves two methods: pressing and extraction (refining).Pressing MethodAlso known as the "physical pressing method," this method involves using external force to squeeze the oil out of the oilseeds without the use of other chemical solvents, thus avoiding the residue of organic solvents in the oil.The pressing process retains the effective components of sunflower seeds to a great extent, including polyunsaturated fatty acids, as well as proteins, dietary fiber, vitamins, trace elements, and other nutrients beneficial to the human body, making it more suitable for specific health supplements.Extraction Method (Refining Method)The oil produced by the extraction process, also known as extracted oil, is obtained by using organic solvents (such as gasoline, ethanol, etc.) to extract the oil from the oilseeds. The extraction method involves using solvent oil (light gasoline No. 6) to extract the oil from the raw material after soaking, followed by high-temperature extraction to remove the oil. Initially, the "oil" extracted is a mixture of organic solvents and oil, which is not edible and must undergo a series of refining processes (such as degreasing, degumming, dehydrating, deodorizing, deacidifying, decolorizing, etc.) before it can be consumed. This oil generally has a lighter color and a weaker or no natural seed flavor. The extraction process can almost extract all the oil from the oilseeds, making it a highly economic and widely used method in the modern oil industry.Production ProcessThe production process includes screening, impurity removal, dehusking, crushing, steaming and frying, pressing, crude oil pressing, coarse filtering, fine filtering, low-temperature crystallization and maturation, low-temperature filtering, and finally, sunflower seed oil.Advantages: Retains almost all the nutrients in sunflower seed oil, has a refreshing taste without greasiness, and is rich in polyunsaturated fatty acids.Disadvantages: Lower oil yield, relatively higher cost.Extraction MethodAdvantages: Very high oil yield, low cost, and higher economic benefits. It is a widely used processing method in the modern oil industry.Disadvantages: Destroys some nutrients, has a minimal residual amount of organic solvents (in compliance with national standards).Sunflower Seed OilOil extracted from sunflower seeds is known as sunflower seed oil. It has a golden color, clarity, and a pleasant aroma, making it the primary cooking oil for Europeans and Russians. Sunflower oil is pure, clear, and fragrant. Due to its rich content of linoleic acid and other health-promoting nutrients, it is hailed as a "health food," "nutrient oil," or "healthy oil" internationally.Sunflower oil is a healthy cooking oil known for its high linoleic acid content. According to Professor Cao Wanxin of the Oil Research and Design Institute of the National Food Reserve Administration in Xi'an, the consumption of appropriate oil products for a long time can significantly improve symptoms of cardiovascular and cerebrovascular diseases such as coronary heart disease, stroke, cerebral thrombosis, arteriosclerosis, and hypertension. Sunflower oil is an excellent choice among healthy oils and has become a preferred oil for consumers and chefs. It ranks third in global consumption among all vegetable oils.Sunflower seed oil contains phytosterols, vitamins, linoleic acid, and other beneficial substances for humans, with a high content of natural vitamin E among all major vegetable oils; the linoleic acid content can reach about 70%.Sunflower seed oil has the ability to reduce serum cholesterol levels, lower triglyceride levels, and has a hypotensive effect. Moreover, sunflower oil is light and transparent, preserves the natural flavor of food during cooking, and has a high smoke point, eliminating the harm of smoke to the human body.Refined sunflower seed oil has a clear, light yellow or greenish yellow color with a pleasant aroma and pure taste. The composition of fatty acids in sunflower seed oil is affected by climatic conditions; cold-region production has about 15% oleic acid and 70% linoleic acid, while warm-region production has about 65% oleic acid and 20% linoleic acid. The human digestibility of sunflower seed oil is 96.5%, and it is rich in linoleic acid, which can significantly reduce cholesterol, prevent vascular hardening, and prevent coronary heart disease. Additionally, the content of physiologically active a-tocopherol in sunflower seed oil is higher than that of most vegetable oils, and the ratio of linoleic acid to vitamin E is balanced, facilitating human absorption and utilization. Therefore, sunflower seed oil is a high-nutrient, beneficial oil for human health.

Cold Pressing Flaxseed Oil Equipment

Cold pressed flaxseed oil is obtained by pressing flaxseeds. Flaxseed is a traditional oil crop in China, and flaxseed oil has been recognized for its value. Oil flax has been cultivated in China for over 600 years and is currently mainly distributed in the north and northwest regions of China, with the highest production in Inner Mongolia, Shanxi, Gansu, and Xinjiang provinces, followed by Jilin, Hebei, Shaanxi, and Qinghai. There is also sporadic cultivation in Tibet, Yunnan, and Guizhou in the southwest region. It is an important economic crop and a major oil crop in China. Flaxseed oil is rich in alpha-linolenic acid, a good source for linolenic acid supplement.FeaturesFlaxseed oil equipment produces oil by pressing the seeds of the flax plant. Flaxseed oil contains linoleic acid, an omega-6 fatty acid, but unlike most vegetable oils, flaxseed oil is dominated by another essential fatty acid—alpha-linolenic acid (ALA), an omega-3 fatty acid.Omega-3 and omega-6 unsaturated fatty acids cannot be synthesized by the human body and must be supplemented through diet, hence they are known as "essential fatty acids." The vegetable oils we commonly consume, such as peanut oil, soybean oil, and sunflower oil, mainly contain omega-6 fatty acids and very little omega-3 fatty acids. This dietary pattern leads to a serious imbalance of omega-3 and omega-6 fatty acids in the body. Scientific research has confirmed that omega-3 unsaturated fatty acids help eliminate factors that cause thrombosis and inflammation and repair damaged cell membranes; while omega-6 polyunsaturated fatty acids have a "double-edged sword" effect on the body: on one hand, they help protect cardiovascular and cerebrovascular health, but in excess, they can harm the body, inducing cardiovascular and cerebrovascular diseases, diabetes, arthritis, allergies, dermatitis, and immune system diseases.Therefore, properly supplementing with flaxseed oil can help improve the imbalance of omega-3 and omega-6 polyunsaturated fatty acids in the existing diet, better maintaining the health of body tissues.

Grape seed oil Pressing Equipment

Grape Seed Oil Equipmentoilseeds refer to plant materials used for oil extraction, generally including plants with an oil content of over 10% that are valuable for oil extraction. Examples include seeds of grapes, soybeans, cotton, sesame, and rapeseed; nuts of peanuts and coconuts; fruits of oil palm and olive; underground tubers of oil yam; embryos of corn and wheat; and rice bran, and others. Grape seed oilseeds can be categorized into edible and medicinal oilseeds based on their economic use. Any raw material that can be used to extract edible oil, such as grape seeds, soybeans, peanuts, cottonseeds, sesame, rapeseeds, tea seeds, corn embryos, and rice bran, is considered an edible oilseed. According to botanical classification, vegetable oilseeds can be divided into herbaceous and woody types. Oilseeds produced by trees or shrubs are called woody oilseeds, such as grape seeds, tea seeds, oil tung, and olive oil, while those produced by herbaceous plants are called herbaceous oilseeds, such as sesame, peanuts, and rapeseeds. Herbaceous oilseeds are the main source of oilseeds, primarily consisting of seeds.Characteristics of Grape Seed Pressing Method for Oil Extraction(1) Strong adaptabilityThe pressing method is suitable for processing various oilseeds and can be applied to production on different scales. It does not require high power equipment and can utilize electricity or other power sources, offering flexibility and convenience, especially in areas with underdeveloped industry or poor transportation.(2) Simple and easy-to-operate processUsually, the oilseeds can be pressed after pretreatment, with a short technological process and low technical requirements for operation. The supporting equipment can be a combination of traditional and modern, with low investment and quick results. When using small oil presses, direct fire can be used to roast the seeds, and whole seeds can be pressed, although the quality of the crude oil obtained may be poorer.(3) Relatively safe productionDuring the production process, the oil press machinery operates smoothly with a slow rotation speed of the main shaft, such as 8 rpm for ZX·18, 15 rpm for ZY·24, and 28-35 rpm for ZX·10. Generally, no accidents will occur as long as the production operation procedures are followed.(4) DisadvantagesThe main disadvantages of the pressing method include a higher residual oil rate in the press cake compared to the leached meal, a significant labor intensity during repair and replacement of wearable parts, and poorer product quality in small-scale plants with rudimentary production conditions.Due to these limitations, especially the higher residual oil rate in the press cake, which can generally reach 5%-8%, it is necessary to integrate the pressing method with the extraction method to further extract the residual oil from the press cake and reduce production costs.

Small-scale Special Oilseed Pressing Equipment

This process is specifically designed and developed for special production lines suitable for high-value-added special small variety oilseed plants. It uses either low-temperature cold pressing oil extraction technology or fragrant hot pressing, preserving the all-natural nature of the oil and the low denaturation of the oilseed protein, creating conditions for protein development. It mainly includes pre-pressing equipment for the production of special oils such as sea buckthorn oil, walnut oil, tea seed oil, wheat germ oil, grape seed oil, evening primrose oil, almond oil, flaxseed oil, perilla oil, and other special oil production technologies.

Flaxseed Oil Equipment

Flaxseed Oil Equipment - Flaxseed Oil Extraction Equipment Developed and Produced by Xinxiang Hongyang Machinery Co., Ltd.Innovation Points:The company proposes a mechanical pressing and pure physical method for the production of flaxseed edible oil without the shell; the domestic extraction of flaxseed edible oil generally adopts the screw press process, using a screw press to extract oil. There is an issue where the oil material must be pressed with the shell, otherwise, the material cannot withstand the pressure and no oil is produced. Meanwhile, pressing with the shell necessarily brings other impurities and oil color darkening problems. Currently, the solution is only through physical and chemical methods for treatment to meet international standards; this project draws on domestic and foreign oil processing technology and equipment, through assembled integrated innovation, mainly uses hydraulic oil pressing equipment, overcomes the shortcomings of the screw oil press, allowing the oil material to be pressed without the shell, thereby reducing subsequent chemical refining, decolorization, and other process treatments, which not only improves product quality but also reduces production costs.