153-0373-2222

138-3908-0089

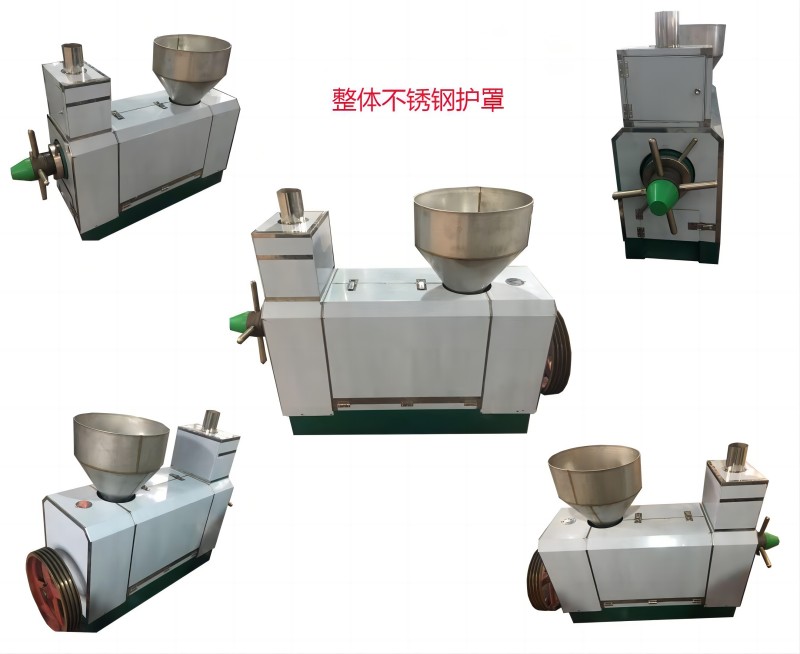

Stainless Steel Oil Press

Before oilseeds are pressed, they should undergo pre-treatment, as the quality of pre-treatment directly affects the oil extraction results. Good pre-treatment can achieve:

a. Increased oil yield;

b. Higher quality oil and oil cake;

c. Improved equipment processing capacity and reduced energy consumption;

d. Ensured equipment safety.

General oilseed pre-treatment includes:

1. Cleaning: Cleaning removes dirt, stones, and metal objects from the oilseeds. Poorly cleaned oilseeds will accelerate parts wear and even damage the oil press, as well as reduce oil yield.

2. Shelling and Separation: To fully utilize the oil press’s production capacity and reduce oil loss, shelled oilseeds like peanuts, tung seeds, cottonseeds, and tea seeds should be shelled and separated before pressing. This is an essential step.

3. Crushing and flaking: rapeseed and soybeans(cold pressing) can generally be pressed in a whole condition, but crushing and flaking the seeds will improve oil yield. Other oil seeds also perform better when crushed and flaked before pressing.

4. Steaming and cooking: the quality of steaming and cooking oilseeds is the key point of increasing oil yield. Steaming and cooking control the moisture content and increase the temperature of oilseeds before pressing. Users can choose suitable steaming and drying equipment to match with the oil press. (Hongyang Company produces the YHCZ series cylindrical cooker, which is available for user selection)