153-0373-2222

138-3908-0089

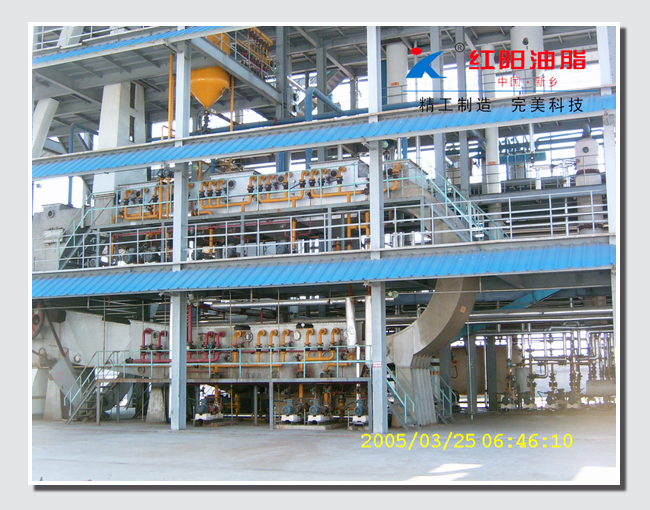

Oil Cake Extraction Equipment (Loop Type Extractor):

the loop type extractor adopts chain drive, and a novel loop shaped design. It has the feature of low speed, stable operation without noise, and low maintenance cost.

The feeding system automatically adjusts the main machine's speed based on the incoming material quantity, maintaining a certain material level in the storage bin. This facilitates the formation of a slight negative pressure inside the extractor, reducing solvent leakage.

The advanced mixed oil circulation principle design helps reduce the amount of fresh solvent required, lowering the residual oil in the meal, increasing the concentration of the mixed oil, and achieving energy-saving goals by reducing evaporation.

The lower material layer design of the extractor focuses on percolation extraction, with the material undergoing a single flip in the bending section, which helps reduce extraction dead spots. However, the meal powder content in the mixed oil is relatively high, and effective treatment is necessary before it can enter the evaporation system.

The Loop type extractor is an important product in the extractor equipment category.