Product Search

Rapeseed Oil Extraction Equipment

The production of rapeseed oil using the extraction method is as follows:Rapeseed Oil Extraction MethodRapeseed oil extraction is based on the principle of extraction, where an organic solvent capable of dissolving oil is selected and brought into contact with the oilseed after pretreatment—either through immersion or spraying. This allows the oil to be dissolved from the oilseed. The method forms a solution of solvent and the dissolved oil, known as mixed oil. By utilizing the difference in boiling points between the selected solvent and the oil, the mixed oil is evaporated and stripped to evaporate the solvent, leaving behind the oil, resulting in crude oil. The evaporated solvent steam is then condensed and recovered for reuse.Advantages of Extraction MethodThe extraction method for oil production is recognized worldwide and can be summarized with the following advantages:1. Low residual oil in mealIn the pressing method, due to the incomplete destruction of oil cells in the pretreatment process and the incomplete denaturation of proteins, the temperature and pressure in the press chamber cannot be very high. As a result, the pressing method cannot extract all the oil from the oilseed, and the residual oil rate in the press cake is relatively high. For example, the residual oil rate in the press cake obtained from various oilseeds pressed by the ZX·18 type press is generally between 5% and 8%. In contrast, the extraction method, whether direct extraction or pre-pressing extraction, can control the residual oil rate in the meal after extraction below 1%.2. High meal qualityCompared to the pressing method, in the production of rapeseed oil using the extraction method, the operation temperature of related processes is generally lower, resulting in less denaturation of proteins in the solid material. Consequently, the quality of the meal is better, which is advantageous for the feeding value of the meal or for extracting plant proteins from the meal.3. Low production costCompared to the pressing method, the extraction method typically uses a more complete production line with a higher degree of mechanization and is easier to achieve production automation. Secondly, the operation personnel in the extraction workshop are fewer, with lower labor intensity. Additionally, the energy consumption in the extraction method is relatively lower. Therefore, the production cost of the extraction method is lower.

Soybean Oil Extraction Equipment

Soybean oil is typically obtained through various methods such as pressing and extraction, resulting in crude oil with many impurities. This crude oil is then refined to produce edible refined oil.Pressing methods can be divided into ordinary pressing and screw pressing. Ordinary pressing is a method of applying pressure to soybeans. This method is now rarely used, especially in large-scale industrial production. Screw pressing involves the installation of a screw shaft in a horizontal cylinder, where pre-processed soybeans enter the screw press. As the soybeans move forward, they are squeezed to extract the oil. This method allows for continuous production but proteins undergo significant changes due to friction and heat generation during the pressing process.Oil extraction by the extraction method utilizes solvents that can dissolve oil. Through wetting, penetration, molecular diffusion, and convection diffusion, the oil is extracted from the meal. The mixed oil, consisting of solvent and oil, is then separated, and the solvent is recovered to obtain crude oil. The commonly used solvents in China's oil industry include hexane and light gasoline. Light gasoline is the most widely used solvent, but it has the drawback of being flammable and explosive, with a complex composition and a wide boiling range. The extraction method yields an oil extraction rate of up to 99%.Differences between Pressing Oil and Extraction Oil1. Different Processing TechniquesPressing oil is produced using the "physical pressing method," while extraction oil is produced using the "chemical extraction method." the physical pressing method requires high quality raw material and then go through selecting seeds, remove impurities, crushing, steaming and then pressing to get oil separated from the oil seeds. In the whole process, it adopts cooking oil seeds, then pressing by oil press and finally filtrate by high-tech natural purification method. This method can help to retain soybean’s original flavor and the oil have rich aroma and rich vitamin E, can be stored longer and contains no additives, solvent residues or soap content. It is a pure natural green food produced by combining modern and traditional techniques.Extraction oil is produced using the organic solvent extraction method, which involves the complete mixing of oilseeds with organic solvents such as "No. 6 light gasoline" (commonly referred to as "No. 6 solvent oil") and then extracted. Therefore, it is difficult to completely remove toxic organic compounds like ethane, and it can only be safely consumed by meeting extremely strict refining standard. Otherwise, it can easily harm the human body. However, during high-temperature refining, some of the nutrient vitamins are inevitably lost. In China, except for a portion of soybean oil produced by pressing, most sunflower oil, soybean oil, cottonseed oil, and other oils are mainly produced using the "No. 6 light gasoline" extraction method.2. Different Nutritional ComponentsPressing soybean oil has a full range of color, aroma, and taste, retaining various nutritional components. Extraction oil is colorless and odorless, and most of its nutritional components are destroyed during processing. The new standard for edible oils drafted by the National Grain Bureau has been implemented, canceling the old standards from 1986 and 1988. The new standard stipulates that pressing soybean oil and extraction soybean oil must be labeled with "pressing" and "extraction" respectively on the product label. With the progress of society and the improvement of people's living standards, the pursuit of nutrition and health in diet has become a goal. Making the soybean oil production process transparent is to inform consumers about the production process of soybean oil, giving consumers the right to know and choose.3. Different Requirements for Raw Materials"Pressing soybean oil" uses the pure physical pressing method, retaining the original flavor of soybeans. Therefore, the requirements for soybean raw materials are very strict, requiring freshness, low acid value, and peroxide value. As a result, the price is relatively high. Additionally, since only pressing is performed, the residual oil in soybean meal is high, and the oil yield from pressing is relatively low. Consequently, the price of pressing soybean oil is relatively high.

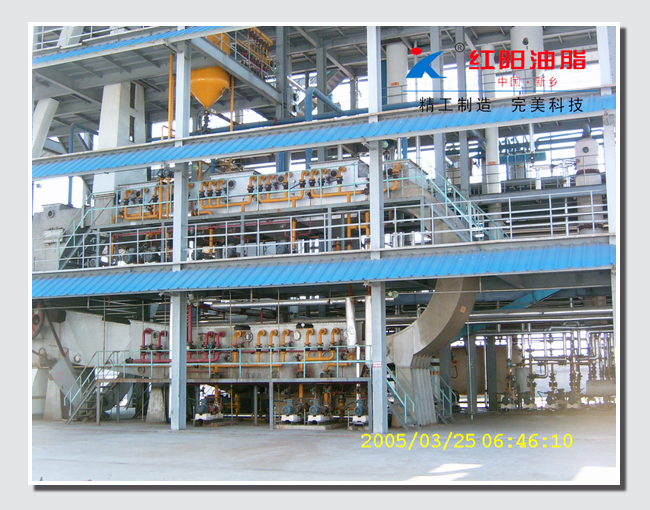

Large Scale Rotary Extraction Equipment

Oil Cake Extraction Equipment:The stainless steel fixed grid plate extractor is one of the modern extraction equipment. Compared to the traditional false bottom flat rotary extractor, it retains the advantages of small power consumption, reliable equipment operation, long service life, convenient maintenance, and good extraction effect, and further improves production capacity, simplifies structure, reduces operating faults, and enhances extraction effect.Main Features:1. It is the most simplified structure among similar extractors.2. The fixed grid plate replaces the false bottom, reducing the number of moving parts and thus reducing faults, improving the safe operation rate, and ensuring reliable operation.3. It has a "self-cleaning" effect and does not require shutdown for cleaning the grid plate.4. It can increase the extraction time of the material, reducing the residual oil rate in the meal.5. It can increase the loading factor and improve the output.Process Flow:The pretreatment material is conveyed by a scraper conveyor into the extraction workshop and falls into the flat rotary extractor through a sealed auger. It is then sprayed with solvent or mixed oil for extraction. After draining, the wet meal falls into the meal hopper and is conveyed through the scraper conveyor and sealed auger into the steaming and de-solventing machine. After de-solventing and drying, it is transported to the finished meal warehouse. The concentrated mixed oil filtered by the extractor flows into the mixed oil tank, then enters a long tube evaporator to separate solvent steam. It then flows into a second long tube evaporator for further separation of solvent steam. After separation, it flows into the stripping tower to remove residual solvent. The crude oil is then transferred to the crude oil tank and sent to the refining workshop. The solvent steam from the long tube evaporator and the second long tube evaporator, the stripping tower, the flat rotary extractor, and the steaming and de-solventing machine is introduced into the condenser for condensation. The condensed liquid flows into the separator for water separation, and the separated solvent returns to the solvent circulation warehouse. The wastewater from the separator and the solvent circulation warehouse flows into the boiling water tank for boiling and then to the water seal pool. The free gases from the top of each device are collected into the condenser for condensation, and the non-condensed gas enters the absorption tower for further solvent capture.Main Economic and Technical Indicators of Flat Rotary Extractor (300T Soybean Extraction as an Example):- Production Capacity: 300 tons per day- Residual Oil in Meal: ≤1% (Soybean)- Solvent Consumption: ≤4 kg/ton of material (No. 6 solvent oil)- Moisture and Volatiles in Crude Oil: ≤0.30%- Electric Consumption: ≤23 KWh/ton of material- Steam Consumption: ≤200 kg/ton of material (0.8MPa)- Moisture in Finished Meal: ≤13% (adjustable)- Residual Solvent in Finished Meal: ≤300 PPM (meeting explosion test standards)

Large Scale Hildebrand Extraction Equipment

Hildebrand Extraction EquipmentHildebrand extractor is a type of solid-liquid extraction equipment used for oil production. The basic working principle is as follows: the flaked or expanded oilseeds enter the extractor, and form a certain height of material layer. At this point, solvent(No. 6 light gasoline) is sprayed onto the oilseeds through the spray pipes, and and reaches a certain liquid level on the surface of material layers. Meanwhile, the chain and scraper driven by the transmission mechanism slowly and uniformly push the oilseeds forward. As the oilseeds are repeatedly sprayed and immersed with solvent(mixed oil), the oil inside the oilseeds is slowly dissolved out and dissolved in the solvent (commonly referred to as mixed oil). The mixed oil flows through the grating plates into the oil collecting tank and is then pumped into the temporary storage tank by the mixed oil pump. It is then transported to the evaporation and stripping section. The mixed oil with a lower density continues to recycle and spay. After nearly one hour of extraction, the oil in the oilseeds is fully extracted. The meal residue after extraction is pushed out of the extractor by the chain scraper and then conveyed into the steaming and de-solventing machine for solvent recovery.Application range:This equipment is suitable for various raw materials extraction, including one time extraction of soybean embryo and rice bran. It is also suitable for extraction of pre-pressed cakes of cottonseed, rapeseed, sesame, tea seed and tung seed, etc.Advantages of hildebrand extractors:-the material is divided into several independent units on the material layer, effectively preventing the flow of mixed oil between the layers and ensureing the concentration gradient between the spraying sections.-each material grid forms an immersion zone so as to reach a better immersion effect.-the chain box is supported by tracks and does not contact with the screen surface so as to extend the screen life.-adopts international popular hydraulic motor dual-axis drive to make the force balanced, operation reliable, and maintenance cost low.-it is more suitable for materials with high oil content and high powder content, and the extraction effect of common oilseeds is better.Economic and Technical Indicator of Hildebrand Extractors(500T/D as an example):- Steam Consumption: ≤280kg/t material (soybean)- Electric Consumption: Installed capacity of 320KW- Solvent Consumption: ≤4kg/t material (No. 6 solvent)- Residual Oil in Meal: ≤1.0%- Moisture in Meal: 12-13% (adjustable)- Solvent Content in Meal: ≤500ppm- Urea Enzyme Activity: 0.05-0.25 (soybean meal)- Crude Oil Extracted - Total Volatile Matter: ≤0.30% - Residual Solvent: ≤300ppm - Mechanical Impurities: ≤0.20%

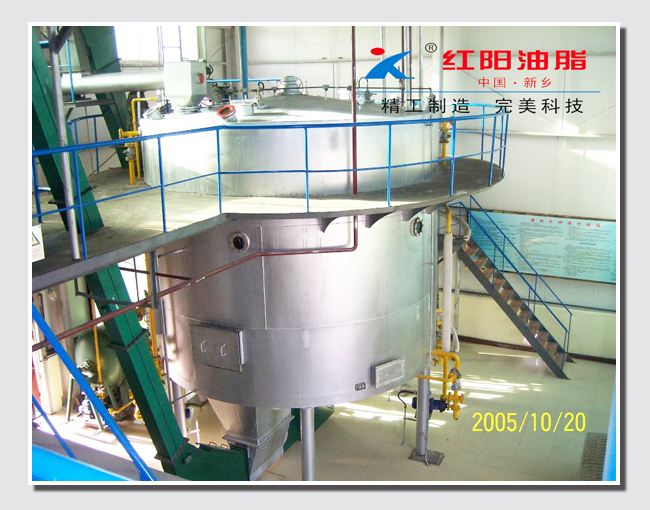

Vacuum Evaporation Extraction Equipment

Introduction:This process employs a full vacuum evaporation process, which improves the quality of crude oil and significantly reduces steam and solvent consumption, thus greatly reducing production costs.Added Benefits:Compared to atmospheric evaporation, the vacuum evaporation process results in lower peroxide values and lighter color in the crude oil, and it also saves energy. Actual calculations show that vacuum evaporation saves about 133kg of steam per ton of raw material, 900kg of cooling water, and reduces solvent consumption by 1-1.5kg, equivalent to a cost savings of 33 RMB per ton of material. For a 200t/d extraction plant, the cost savings can be nearly 2.4 million RMB a year.Advantages:(1) Energy Saving: The secondary steam from the Hongyang steaming and de-solventing machine is used as the heat source for the first evaporation, and the negative pressure reduces the evaporation temperature, reducing the steam and circulating water usage throughout the production line. After implementing vacuum evaporation, the quality of the oil product is improved, water washing and degumming is easier, and the amount of bleaching clay used is reduced. The solvent consumption in the workshop also decreases due to negative pressure operation.(2) Improved Quality of Crude Oil: The operating temperature is lower than atmospheric pressure, resulting in smaller peroxide values, lighter color, and usually a residual solvent content of less than 0.02%, thus improving the quality of the crude oil.(3) Reduced Condensation Area: The condensation system has less burden, so the condensation area can be reduced by 40% compared to atmospheric evaporation.(4) Enhanced Workshop Safety: The entire system operates under a slight negative pressure environment, reducing the leakage of solvent and improving the safety of the extraction workshop.(5) Improved System Stability: An automatic control system is set up, with key parameters of the system controlled by automatic instruments, reducing the labor intensity of workers and enhancing the stability of the system operation.(6) Extended Equipment Life: Poor quality oil from atmospheric evaporation leads to more protein and mucilage buildup, which can clog the evaporation tubes over time, affecting performance and shortening the equipment's lifespan.Process Flow:The pretreatment material is conveyed by a scraper conveyor into the extraction workshop and falls into the flat rotary extractor through a sealed auger. The material is then sprayed with solvent or mixed oil for extraction. After draining, the wet meal falls into the meal hopper and is conveyed through the scraper conveyor and sealed auger into the steaming and de-solventing machine. After de-solventing and drying, it is transported to the finished meal warehouse. The concentrated mixed oil filtered by the Hongyang extractor flows into the mixed oil tank, then enters a long tube evaporator to separate solvent steam. It then flows into a second long tube evaporator for further separation of solvent steam. After separation, it flows into the stripping tower to remove residual solvent. The crude oil is then transferred to the crude oil tank and sent to the refining workshop. The solvent steam from the steaming and de-solventing machine is used as the heat source in the long tube evaporator, and a vacuum pump is used to create a vacuum, operating the entire mixed oil evaporation system under a vacuum state. The solvent steam from the long tube evaporator and the second long tube evaporator, the stripping tower, the flat rotary extractor, and the steaming and de-solventing machine is introduced into the condenser for condensation. The condensed liquid flows into the separator for water separation, and the separated solvent returns to the solvent circulation warehouse. The wastewater from the separator and the solvent circulation warehouse flows into the boiling water tank for boiling and then to the water seal pool. The free gases from the top of each device are collected into the condenser for condensation, and the non-condensed gas enters the absorption tower for further solvent capture.Main Specifications:daily capacity: 80ton, 100ton, 150ton, 200ton, 300ton, 450ton, 600ton, 800ton.Main Equipment:rotary extractor, desolventizer, condenser, long tube evaporator, stripping tower, absorption tower, vacuum pump, scraper conveyor, sealed conveyor, etc.

Rice Bran Oil Extraction Equipment

Rice bran oil equipment, also known as rice bran oil pressing equipment or rice oil equipment, is a specialized machinery used for extracting oil from rice bran.Rice is a major grain crop in China, and rice bran is a byproduct of rice processing, with an annual output of approximately 10 million tons, making it a widely available oil resource. Rice bran typically accounts for 8% to 12% of the whole brown rice, and the oil content in rice bran ranges from 14% to 24%. Due to its tendency to spoil easily and its unsuitability for long-term storage, rice bran is commonly used as animal feed. Only about 10% of the rice bran is used for oil pressing or further processing into higher-value products like phytic acid calcium, inositol, and oryzanol. With the continuous advancement of science and technology, the stability of rice bran storage has been improved by inactivating the lipase and peroxidase enzymes in rice bran, extending the storage time and making it a better raw material for oil processing.The extruded rice bran extraction process is similar to that of soybean and cottonseed cake, involving four main systems: material extraction, wet meal desolventing, mixed oil evaporation, and solvent recovery. However, the material characteristics of extruded rice bran also determine the unique aspects of its extraction process.

Loop Type Extraction Equipment

Oil Cake Extraction Equipment (Loop Type Extractor):the loop type extractor adopts chain drive, and a novel loop shaped design. It has the feature of low speed, stable operation without noise, and low maintenance cost.The feeding system automatically adjusts the main machine's speed based on the incoming material quantity, maintaining a certain material level in the storage bin. This facilitates the formation of a slight negative pressure inside the extractor, reducing solvent leakage.The advanced mixed oil circulation principle design helps reduce the amount of fresh solvent required, lowering the residual oil in the meal, increasing the concentration of the mixed oil, and achieving energy-saving goals by reducing evaporation.The lower material layer design of the extractor focuses on percolation extraction, with the material undergoing a single flip in the bending section, which helps reduce extraction dead spots. However, the meal powder content in the mixed oil is relatively high, and effective treatment is necessary before it can enter the evaporation system.The Loop type extractor is an important product in the extractor equipment category.

Sunflower Oil Extraction Equipment

Sunflower oil equipment, also known as sunflower seed oil extraction equipment, is currently developed and produced by companies such as Xinxiang Hongyang. Its significance lies in extracting the high-nutrient edible oil from sunflower seeds.raw material and ingredientsSunflower seeds, the fruit of the sunflower, are used for both consumption and oil production. Sunflower seeds are rich in unsaturated fatty acids, various vitamins, and trace elements, and with their pleasant taste, they have become a popular snack and source of edible oil.Each 100 grams of sunflower seeds contain 597 calories, 23.9 grams of protein, 49.9 grams of fat, 13 grams of carbohydrates, 72 milligrams of calcium, 5.7 milligrams of iron, 238 milligrams of phosphorus, 562 milligrams of potassium, 5.5 milligrams of sodium, 2.51 milligrams of copper, 264 milligrams of magnesium, 6.03 milligrams of zinc, 1.21 micrograms of selenium, 5 micrograms of vitamin A, 0.36 milligrams of vitamin B1, 0.2 milligrams of vitamin B2, 34.53 milligrams of vitamin E, 0.03 milligrams of carotene, 280 micrograms of folic acid, and 4.8 milligrams of niacin.Principle and ProcessThe production process of sunflower oil generally involves two methods: pressing and extraction (refining).Pressing MethodThe pressing method, also known as "physical pressing," involves using external force to squeeze the oil out of the oilseeds without the use of other chemical solvents, thus avoiding the residue of organic solvents in the oil.The pressing process retains the effective components of sunflower seeds to a great extent, including polyunsaturated fatty acids, as well as proteins, dietary fiber, vitamins, trace elements, and other nutrients beneficial to the human body, making it more suitable for specific health supplements.Sunflower Oil Extraction (Refining Method)The extraction method, also known as the refining method, involves using organic solvents (such as gasoline, ethanol, etc.) to extract the oil from the oilseeds. The Hongyang extraction method uses solvent oil (light gasoline No. 6) to extract the oil from the raw material after soaking, followed by high-temperature extraction to remove the oil. Initially, the "oil" extracted is a mixture of organic solvents and oil, which is not edible and must undergo a series of refining processes (such as degreasing, degumming, dehydrating, deodorizing, deacidifying, decolorizing, etc.) before it can be consumed. This oil generally has a lighter color and a weaker or no natural seed flavor. The extraction process can almost extract all the oil from the oilseeds, making it a highly economic and widely used method in the modern oil industry.Production ProcessThe production process includes screening, cleaning impurities, shelling, crushing, steaming and frying, pressing, crude sunflower seed oil pressing, coarse filtering, fine filtering, low-temperature crystallization and maturation, low-temperature filtering, and finally, sunflower seed oil.Advantages: Retains almost all the nutrients in sunflower seed oil, has a refreshing taste without greasiness, and is rich in polyunsaturated fatty acids.Disadvantages: Lower oil yield, relatively higher cost.Sunflower Oil ExtractionAdvantages: Very high oil yield, low cost, and higher economic benefits. It is a widely used processing method in the modern oil industry.Disadvantages: Destroys some nutrients, has a minimal residual amount of organic solvents (in compliance with national standards).Sunflower Seed OilOil extracted from sunflower seeds is known as sunflower seed oil. It has a golden color, clarity, and a pleasant aroma, making it the primary cooking oil for Europeans and Russians. Sunflower oil is pure, clear, and fragrant. Due to its rich content of linoleic acid and other health-promoting nutrients, it is hailed as a "health food," "nutrient oil," or "healthy oil" internationally.Sunflower oil is a healthy cooking oil known for its high linoleic acid content. According to Professor Cao Wanxin of the Xi'an Oil Research and Design Institute of the National Food Reserve Administration, in the 21st century, cardiovascular diseases such as coronary heart disease, stroke, cerebral thrombosis, arteriosclerosis, and hypertension are increasing. Long-term consumption of suitable oil products can significantly improve these symptoms. Sunflower oil is an excellent choice among healthy oils and has become a preferred oil for consumers and chefs. It ranks third in global consumption among all vegetable oils.Sunflower seed oil contains phytosterols, vitamins, linoleic acid, and other beneficial substances for humans, with a high content of natural vitamin E among all major vegetable oils; the linoleic acid content can reach about 70%. Sunflower seed oil can reduce serum cholesterol levels, lower triglyceride levels, and has a hypotensive effect. Moreover, sunflower oil is light and transparent, preserves the natural flavor of food during cooking, and has a high smoke point, eliminating the harm of smoke to the human body.Refined sunflower seed oil has a clear, light yellow or greenish yellow color with a pleasant aroma and pure taste. The composition of fatty acids in sunflower seed oil is affected by climatic conditions; cold-region production has about 15% oleic acid and 70% linoleic acid, while warm-region production has about 65% oleic acid and 20% linoleic acid. The human digestibility of sunflower seed oil is 96.5%, and it is rich in linoleic acid, which can significantly reduce cholesterol, prevent vascular hardening, and prevent coronary heart disease.Furthermore, the content of α-tocopherol, a strong physiological active substance, in sunflower seed oil is higher than that in general vegetable oils. Moreover, the ratio of linoleic acid content to vitamin E content is relatively balanced, which is conducive to human absorption and utilization. Therefore, sunflower seed oil is a high-nutrient, beneficial oil for human health.

Rice Bran Oil Extraction Equipment

rice oil equipment, also known as rice oil equipment, is developed and produced by Xinxiang Hongyang Company. Its significance lies in extracting the high-nutrient edible oil from rice bran.Principle and ProcessThe production process of rice bran oil generally adopts the extraction method (refining method) developed by Xinxiang Hongyang Company.Extraction Method (Refining Method)The extraction method, also known as the refining method, involves using organic solvents (such as gasoline, ethanol, etc.) to extract oil from the oil material. The Hongyang extraction method uses solvent oil (light gasoline No. 6) to extract the oil from the raw material after soaking, followed by high-temperature extraction to remove the oil. Initially, the "oil" extracted is a mixture of organic solvents and oil, which is not edible and must undergo a series of refining processes (such as degreasing, degumming, dehydrating, deodorizing, deacidifying, decolorizing, etc.) before it can be consumed. This oil generally has a lighter color and a weaker or no natural seed flavor. The extraction process can almost extract all the oil from the oil material, making it a highly economic and widely used method in the modern oil industry.Production Processthe rice bran extraction process includes rice bran material, screening, destoning, expanding(pelletizing), solvent extraction, rice bran mixed oil, heating and fractionation, fine filtration, and finally rice bran oil.Rice Bran OilRice bran oil, pressed or extracted by Equipment from Xinxiang Hongyang Machinery Co., Ltd, is divided into two types: rice bran oil and rice bran essence oil: the oil extracted from rice bran (the protective layer of rice grains such as pericarp, seed coat, and exocarp) is called rice bran oil, and the oil extracted from rice bran essence (the pure rice embryo and aleurone layer) is called rice bran essence oil.GB 19112—2003 "Rice Bran Oil" is the national standard for edible rice bran oil in China. However, with people's increasing attention to the safety of edible oils, the Oilseeds and Oil Technology Group of the National Standardization Committee of Cereals and Oils hosted a national standard seminar for Rice Bran Oil in Hefei, Anhui, on July 3, 2013. The group leader, Professor He Dongping of Wuhan Light Industry University, said that the new national standard for "Edible Rice Bran Oil" will be completed in the second half of this year, submitted for approval and review in the first half of next year, and is expected to be promulgated in the second half of next year. The invention of "Rice Bran Essence Oil" will change the original standard for edible rice bran oil.Rice, an important food crop in Asia and even the world. 64% of the nutrition in rice is in the rice bran and rice embryo, about 60% of the nutrition is hidden in the aleurone layer and embryo (rice bran essence). Currently, rice bran oil is extracted from the rice bran and embryo, and 150 kg of rice can produce 1 liter of first-grade rice bran oil. In Japan, Southeast Asia, and Taiwan, it is also known as brown rice oil, with a long history of research and development and consumption. In the future, rice bran oil will be separated from the rice bran essence.Rice bran oil is unique in containing oryzanol, and its vitamin E content is much higher than that of other edible oils. In addition, the smoke point of rice bran oil is relatively high, with less smoke than other household oils during frying. Each 100 grams of rice bran oil contains 23.2 grams of saturated fatty acids, 42.2 grams of monounsaturated fatty acids, and 34.5 grams of polyunsaturated fatty acids, with a ratio close to 1:1:1, approaching the recommended standard of the World Nutrition Association. It is a high-quality natural healthy oil.

Small scale tank group oil extraction equipment

The tank-group extraction unit is a type of equipment used for oil extraction in early and current domestic small-scale extraction oil factories.This Hongyang extraction unit is a cylindrical container with a disc-shaped head. At the bottom of the cylindrical tank, there is a false bottom made of two layers of 8mm diameter perforated screens, with hemp bags or palm fiber in between. The false bottom is tightly mounted on a lower grated iron frame to withstand the weight of the material and solvent, as well as the steam pressure during the "downward pressure" operation (usually around 98kPa). After the false bottom is installed, only liquids like mixed oil and solvent can pass through, while meal particles cannot. The top cover is equipped with an inlet pipe, and there is an outlet for meal at the tank body, with various pipes for operation mounted on the shell.The characteristics of tank-group extraction are simple equipment, low investment, small solvent consumption and energy consumption, strong adaptability to various oil materials, and suitable for small-scale enterprises producing multiple varieties in small batches.Attentions during the operation of the tank-group extractor:1. First, the pre-pressed cake is conveyed by a screw conveyor into the extraction workshop and lifted by a bucket elevator to the overhead auger. Then it enters an inclined storage bin or directly enters the Hongyang extraction tank to shorten the loading time of the extraction tank.2. Open the top cover of the extraction tank, fill it with material until full, and then seal and tighten the top cover.3. Start to introduce fresh solvent, first open the solvent pump and valves to draw from the solvent circulation tank, open the steam valve to heat the solvent in the preheater. When the solvent temperature reaches 45-50°C, it is then pumped through the spray pipe into the Hongyang extraction tank until it is full. (The solvent should be 20-50mm above the cake surface) Open the free gas valve for normal immersion.4. Immersion time is 10-15 minutes. Turn on the mixed oil pump to collect from the tank below the Hongyang oil extraction tank and pump it into the tank for circulation for 5 minutes or directly pump it into Tank 2 until it is full with solvent oil. If the solvent oil is insufficient, add fresh solvent oil.5. Immersion time in Tank 2 is 15-20 minutes, pump the mixed oil into Tank 3 for immersion, immersion time is 10-15 minutes, then pump the mixed oil into Tank 4 for immersion for 10 minutes. The mixed oil is circulated 3-4 times. If the concentration of the mixed oil is not enough, it can be pumped into the mixed oil temporary storage tank for circulation.6. The mixed oil collected in the tank below the extraction tank is pumped through the filter into the mixed oil temporary storage tank for settling. At the same time, 6oBe' brine is pumped from the brine tank into the mixed oil temporary storage tank to precipitate fine debris.

Small scale rotary extraction production line

Oil Cake Extraction Equipment:The stainless steel fixed grid plate extractor is one of the modern extraction equipment, which retains the advantages of small power consumption, reliable equipment operation, long service life, convenient maintenance, and good extraction effect compared to the traditional false bottom flat rotary extractor. It also has the advantages of high output, simplified structure, fewer operating faults, and good extraction effect.vegetable oil extraction complete set equipment is a continuous oil production equipment, which utilizes the action of selected organic solvents to dissolve oil. Through soaking and spraying, the oil is extracted from oil cakes or oil seeds, which can be used for the extraction of rapeseed, peanut, cottonseed, sesame, and all other oil crops and pre-pressed cakes. It can also be used for the single extraction of certain oil crops (such as soybeans).The main advantages of Hongyang's extraction method for oil production: firstly, the oil yield is high. Currently, in China, the oil yield of oil cakes using pressing and screw methods is above 5%, while the oil yield of oil cakes using extraction method is below 1%. Moreover, the meal extracted from soybeans in one-time extraction is of high quality due to the low temperature, high protein content, and high utilization value, which can be widely used as food raw materials.Hongyang's extraction method for oil production has the advantages of low processing cost, high oil yield, high labor efficiency, low labor intensity, safe and reliable equipment, convenient operation and maintenance, and good environmental hygiene conditions, which other oil production methods can not catch up with.Main Features:1. It is the most simplified structure among similar extractors.2. The fixed grid plate replaces the false bottom, reducing the number of moving parts and thus reducing faults, improving the safe operation rate, and ensuring reliable operation.3. It has a "self-cleaning" effect and does not require shutdown for cleaning the grid plate.4. It can increase the extraction time of the material, reducing the residual oil rate in the meal.5. It can increase the loading factor and improve the output.Process Flow:The pretreatment material is conveyed by a scraper conveyor into the sealed auger in the extraction workshop, falling into the flat rotary extractor. It is then sprayed with solvent or mixed oil for extraction. After draining, the wet meal falls into the meal hopper and is conveyed through the scraper conveyor and sealed auger into the steaming and de-solventing machine. After removing the solvent through steaming and drying, it is transported to the finished meal warehouse. The concentrated mixed oil filtered by the extractor flows into the mixed oil tank, then enters a long tube evaporator to separate the solvent steam. It then flows into a second long tube evaporator for further separation of solvent steam. After separation, it flows into the stripping tower to remove residual solvent. The obtained crude oil enters the crude oil tank and is sent to the refining workshop. The solvent steam from the long tube evaporator, the second long tube evaporator, the stripping tower, and the Hongyang brand flat rotary extractor is introduced into the condenser for condensation. The condensed liquid flows into the separator for water separation, and the separated solvent returns to the solvent circulation warehouse. The wastewater from the separator and the solvent circulation warehouse flows into the boiling water tank for boiling and then to the water seal pool. The free gases from the top of each device converge into the after-condenser for condensation, and the non-condensed gas enters the absorption tower for further solvent capture.Main Economic and Technical Indicators of Flat Rotary Extractor (300T Soybean Extraction as an Example):Production Capacity TD 300 tons per dayMeal Residual Oil % ≤1 (Soybean)Solvent Consumption kgT Material ≤4 (No. 6 solvent oil)Crude Oil Moisture and Volatiles % ≤0.30Electric Consumption KWhT Material ≤23Steam Consumption KGT Material ≤200 (0.8MPa)Finished Meal Moisture % ≤13 (Adjustable)Finished Meal Residual Solvent ≤300PPM (Meets explosion test standards)

Small and medium-sized rotary extraction production line

The complete set of extraction equipment is the leading product in the oil market, with rich experience and mature technology in the design and manufacture of extraction equipment. Through the research and development of the scientific and technical personnel of Xinxiang Hongyang Machinery Co. Ltd, the entire set of extraction process has been perfected to have significant characteristics of energy saving, environmental protection, low consumption, and high efficiency. It can be used for the extraction of rapeseed oil, soybean oil, cottonseed oil, tea seed oil, and tung oil.Extraction System Process Analysis:1. Fixed grid plate extractor manufactured by Xinxiang Hongyang Company is widely applicable, easy to operate and manage, and requires no maintenance during use. Since the grating plate is made of fixed stainless steel, it has characteristics of corrosion resistance and wear resistance, resulting in a long service life. This overcomes the drawbacks of heavy maintenance workload and high maintenance costs. The fixed grid plate extractor can effectively promote material forward movement to ensure uniform immersion under the flipping state, with good solvent penetration, reducing the residual oil in the meal by 0.5%. During the production process, the material is in continuous relative motion, preventing the formation of "bridge" phenomena and facilitating smooth operation and process connection. The grating plate is arranged in a trapezoidal pattern with a self-cleaning feature, preventing blockage. The falling material does not cause vibration, thus purifying the production environment. The drainage effect is good, and the matching of grid bar density and immersion and drainage section gaps is designed according to different materials, which is conducive to the formation of the liquid level and drainage effect, reducing the load on the steam stripper.2. The siphon spray nozzle designed by Hongyang Company has good process performance and uniform and stable intermittent spraying speed, which can improve spraying quality and minimize the residual oil in the meal.3. The new process of two-stage spraying and continuous overflow of mixed oil from the oil bin is used. This process increases the solvent spraying volume without increasing the solvent ratio, increases the number of washing times and duration, improves the mixed oil concentration, and effectively ensures the residual oil index in the meal. Practice has proven that the new two-stage spraying process also helps reduce the load of the evaporation and condensation recovery system, ensuring further reduction in solvent and steam consumption.4. The variable frequency speed control device of the extractor can be freely adjusted according to different materials, required output, and process effects, providing a convenient and reliable solution.5. The design capacity of the extractor is large, with a high material layer, and there is usually a 20-40% yield reserve, which is conducive to increasing output and improving efficiency.