Product Search

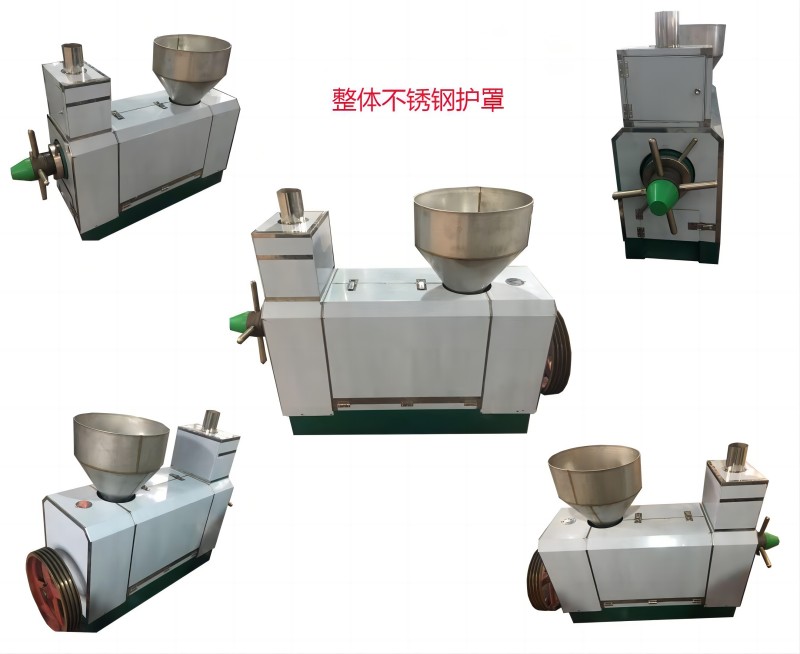

Stainless steel screw oil press

Stainless Steel Oil PressBefore oilseeds are pressed, they should undergo pre-treatment, as the quality of pre-treatment directly affects the oil extraction results. Good pre-treatment can achieve:a. Increased oil yield;b. Higher quality oil and oil cake;c. Improved equipment processing capacity and reduced energy consumption;d. Ensured equipment safety.General oilseed pre-treatment includes:1. Cleaning: Cleaning removes dirt, stones, and metal objects from the oilseeds. Poorly cleaned oilseeds will accelerate parts wear and even damage the oil press, as well as reduce oil yield.2. Shelling and Separation: To fully utilize the oil press’s production capacity and reduce oil loss, shelled oilseeds like peanuts, tung seeds, cottonseeds, and tea seeds should be shelled and separated before pressing. This is an essential step.3. Crushing and flaking: rapeseed and soybeans(cold pressing) can generally be pressed in a whole condition, but crushing and flaking the seeds will improve oil yield. Other oil seeds also perform better when crushed and flaked before pressing.4. Steaming and cooking: the quality of steaming and cooking oilseeds is the key point of increasing oil yield. Steaming and cooking control the moisture content and increase the temperature of oilseeds before pressing. Users can choose suitable steaming and drying equipment to match with the oil press. (Hongyang Company produces the YHCZ series cylindrical cooker, which is available for user selection)

Hydraulic Oil Press

Hydraulic Oil PressXinxiang Hongyang Machinery Co., Ltd. (formerly Xinxiang Hongyang Oil Machinery Factory), located in the National Economic and Technological Development Zone of Xinxiang City, Henan Province, China, is a long-established manufacturer of oil processing equipment. As a member of the China Cereals and Oils Association and the China Feed Industry Association, and a governing unit of the Xinxiang Charity Federation, the company successfully transformed from an old factory in 2004 into a modern oil engineering technology enterprise that integrates product research and development, manufacturing, sales, service, and import and export trade.

Single Oil Press Machine

Basic Concept of Oil Press1. Compression Curve of the Pressing Chamberin the pressing chamber of Xinxiang Hongyang Brand screw oil press, due to the increasing width of pressing screw threads, the decreasing screw pitch and the thickening spiral diameter, etc, after raw material enters to feeding section, the material is propelled and compressed as the pressing screw rotates. The degree of compression changes as the material moves through the pressing chamber. Depicting the variation in the compression degree of raw material as it was propelled through the pressing chamber into a drawing, which is called compression curve of pressing chamber. The compression curve of pressing chamber runs as Figure 5-1Figure 5-1 Compression Curve of the Pressing ChamberFrom Figure 5-1, it can be seen that the compression process of the material in the pressing chamber is divided into three sections, analyzed as follows:1. Feeding Section: In the feeding section, the material starts to be compressed, expelling air and moisture, undergoing plastic deformation, and beginning to release oil. Therefore, a small amount of oil droplets and bubbles can be seen at the front end of the pressing cage.2. Pressing Section: The space in the pressing chamber in the pressing section decreases rapidly and regularly. The material is subjected to intense pressure, causing the particles to combine and form a continuous porous mass that expels a large amount of oil. During this process, the material also experiences various types of friction while being compressed.Specifically, pressing screw interrupt, pressing chamber’s knife bar, pressing rod edge’s shearing action cause raw material displacement, breakage and mixing, which continually open oil pathway, allowing for rapid and thorough oil extraction3. Cake Forming Section: In the cake forming section, the material has formed into tile-shaped cakes that advance almost as a single unit, resulting in significant axial compression resistance. At this stage, the compressibility of the tile-shaped cakes is minimal, but it is necessary to maintain high pressure to ensure thorough oil drainage. This process should be extended for an appropriate amount of time, and the axial resistance should be reduced (the geometric dimensions of the screw change very little at this point). If the pressure is reduced too early, the hot cake will expand and loosen, reabsorbing oil, which is detrimental to pressing. The discharged cakes generally expand slightly due to elasticity or expansion.2. Compression Ratio and Total Compression Ratio1. Free Volume of the Screw: The free volume of the screw refers to the space volume enclosed by the screw in each lead (pitch) within the pressing chamber.2. Compression Ratio: The compression ratio is the ratio of the free volumes of the screw in two adjacent leads. If the free volumes of the screw in two adjacent leads are Vn and Vn+1, respectively, then the compression ratio is:3. Total Compression Ratio: The total compression ratio is the ratio of the free volume of the first lead where the material enters to the free volume of the lead at the cake discharge end. If the free volume of the first lead is V_in and the free volume of the lead at the cake discharge end is V_out, the total compression ratio ε is: